2014

Revolutionizing Production: Embracing Speed, Stock Printing, and Innovative Solutions

The adoption of the new printing process marked a significant turning point for their business, triggering a change in direction. The increased speed brought about lower printing costs overall, but it required adjustments to their on-demand production model. Through negotiations with the printer, they agreed to send a minimum of 2,000 linear metres every two weeks. While their website began generating orders and wholesale sellers in Australia were moving product, the demand did not reach 200 rolls. Consequently, they started printing stock to meet their quota.

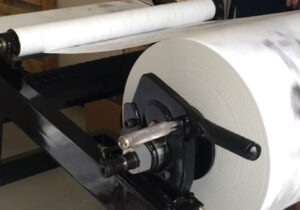

Their new production system proved successful, allowing them to fulfill orders within approximately 21 days. With the reduction in production workload, they gained precious time to focus on marketing and further developing their website. The Dotrix printer had the capacity to accommodate reams of wallpaper up to 120cm in diameter. Taking advantage of this capability, they placed an order for a half container of these larger reams from the European mill. However, the larger quantities posed a challenge in handling the received rolls. To address this, they enlisted the expertise of a long-time friend’s father to develop a re-roller, affectionately named ‘The Yalloroi.’ This impressive piece of engineering facilitated the re-rolling of the larger reams into smaller rolls that could fit onto the back of their trimmer.